Intelligent E-nose

The Meat Quality Sensor is a breakthrough IoT solution that combines biology, chemistry, and technology into one tool to assess the expiration dates of meat and fish.

Intelligent E-nose

The Meat Quality Sensor is a breakthrough IoT solution that combines biology, chemistry, and technology into one tool to assess the expiration date and freshness of meat and fish.

Todays methods

There’s currently no tool in the food industry that can give a freshness indication or calculate fish and meat’s expiration date.

The industry today adds a buffer to the safe limits from microbial point checks to accommodate for deviations in treatment and storage conditions. In the food industry, the daily assessment of freshness and expiration is done by the human senses or strictly following overcautious labelling.

SENSORY ASSESSMENT

Human senses i.e. smelling and vision

GENERIC CURVES

Online curves based on generic data with a considerable buffer

RULE OF THUMB

Following company standards to set expiration dates

MICROBIAL ANALYSIS

Often overcautious labeling based on historical data

Introducing AmiNIC’s Meat Quality Sensor

A powerful tool for the food industry that provides an objective measurement of the expiration dates and freshness of meat and fish. Our sensor has been tested and validated in collaboration with universities, RTOs, and end-users to ensure the best solution for the food industry.

Our sensor is designed to provide accurate and in-situ measurements, improving quality control and reducing waste. With our technology, you no longer need to rely on subjective assessments or overly-cautious labelling practices.

Features

Food compliant design

Food-approved material and hygenic design based on user feedback and developed in collaboration with industrial designers and food-equipment experts.

Remote data storage

Data is uploaded to a cloud service which the user gets access to.

Data on freshness and expiry can be shared along the value chain if desired.

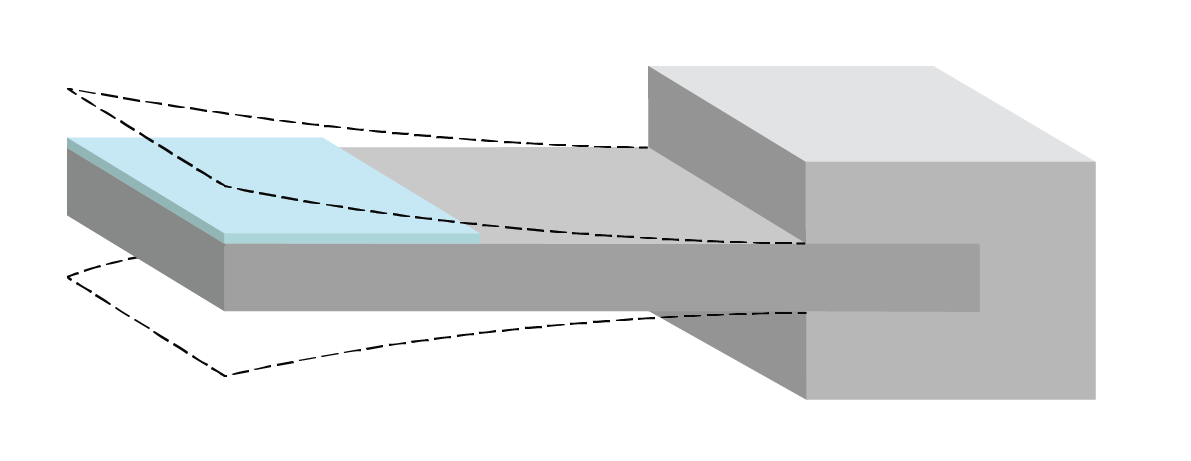

Cartridge solution

Our cartridges contain the technology that enables measurements of cadaverine. Each cartridge can measure for 2+ months.

Preventing cross-contamination

Exchangable and machine- washable mouthpieces prevents cross-contamination between measurements.

Inside the tool

The cartridge hosts the State-of-the-art e-nose solution; a tailor-made MicroElectroMechanicalSystem

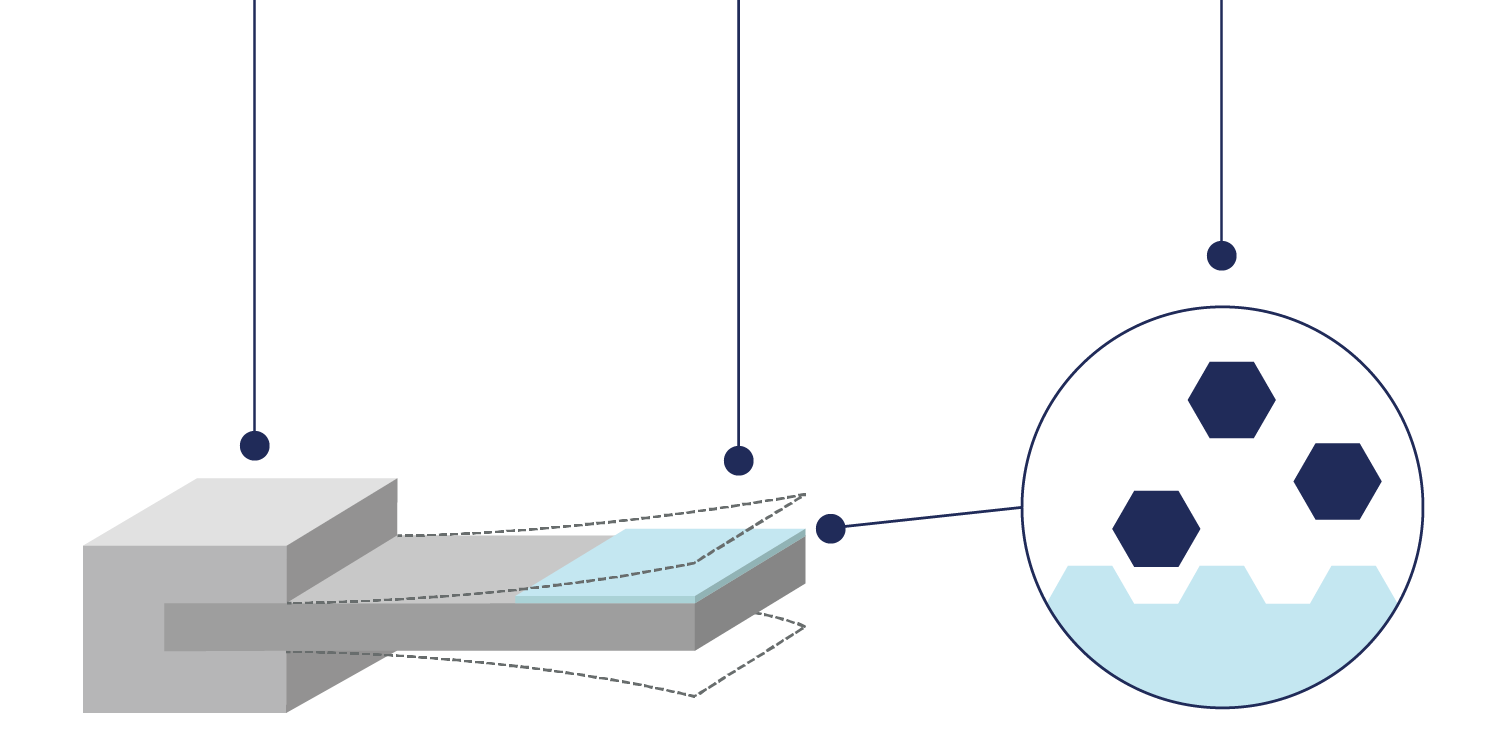

Micro Cantilever

A micro cantilever that acts as a micro scale where changes in mass are calculated electrically.

Selective Binder

The binder on the cantilever surface attracts biomarker molecules that can weigh the cantilever down, making it possible to do measurements.

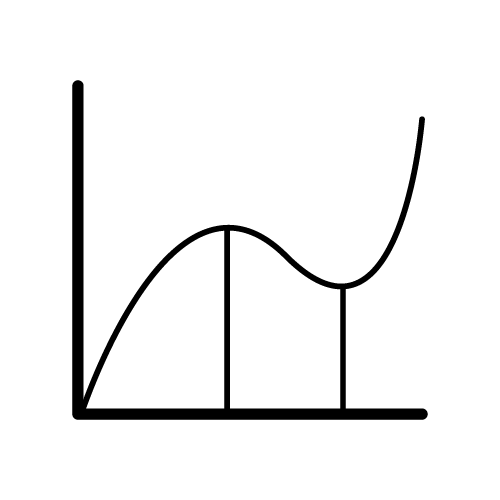

Freshness biomarker

Concentrations of a volatile freshness biomarker in meat and fish evolves predictably, enabeling freshness-predictions.

AmiNIC ApS

+45 28 14 20 35

Jernbanegade 57

5500 Middelfart

Denmark

CVR: 40139265

AmiNIC ApS © 2023